Plumbing Trap – Plumbing Trap Types | Types of Traps In Plumbing | Gully Trap | Types of Drain Traps | Different Types of Traps

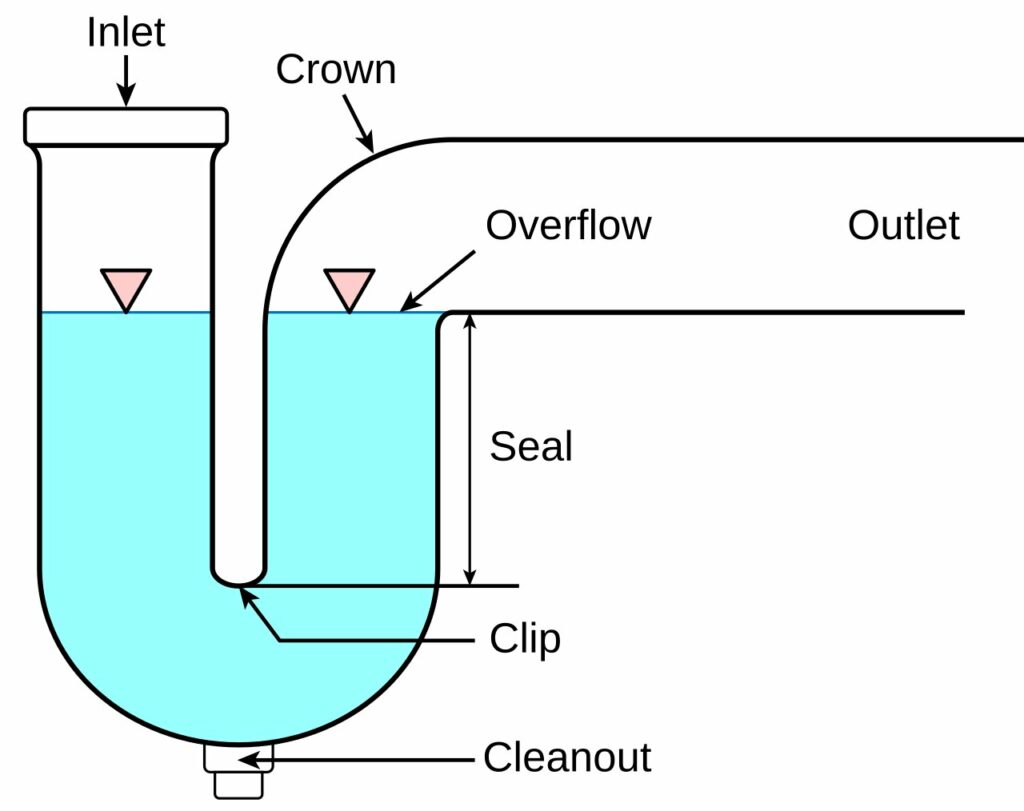

A trap is a U-shaped section of pipe in plumbing that is designed to trap liquid or gas and prevent unwanted flow, most notably sewer gases from entering buildings while allowing waste materials to pass through.

Traps are used in oil refineries to keep hydrocarbons, as well as other dangerous gases and chemical fumes, from escaping through drains. The same feature is used in heating systems to prevent thermo-siphoning, which allows heat to escape to places where it is not wanted.

Similarly, some pressure gauges are connected to systems via U bends in order to maintain a local gas while the system is running on liquid. They can be disguised as complete loops of pipe for a decorative effect, creating more than one U for added efficacy.

What Is Plumbing Trap?

A plumbing trap is a simple shape-bending pipe device that allows waste to pass through. It also holds fluid to prevent sewer gases from entering the structure. In most domestic applications, U, J, Q, or S-shaped pipes are found just beneath or within a plumbing fixture.

A P-shaped plumbing trap, on the other hand, is the most popular choice. There are many different types of plumbing traps on the market.

Plumbing is a type of work that is primarily concerned with sewage disposal and water supply. The plumbing pipes framework will remain odourless as long as it is properly planned and installed. The highlights of a plumbing trap are as follows.

It could be built into the machine as an essential trap, as in some European WC models, or it could be a separate fitting called a joined trap, which is connected to the waste or foul water outlet of apparatuses.

The traps should have a self-cleaning feature. Cleaning traps for use in homegrown waste should be useful. In all states of a stream, a good trap should keep an effective water seal.

Plumbing traps hold a small amount of water and are located beneath or inside a pipe apparatus. The holding water creates a water seal, preventing foul gases from entering the structure of the channel pipes.

As a result, traps are installed in all pipe installations, such as sinks, washbasins, baths, latrines, and so on. This article explains the benefits of traps, as well as the various types of traps.

Types of Traps in Plumbing

Plumbing Trap Types – The following are the various types of plumbing traps:

- Bell Trap

- Bottle Trap

- Building Trap

- Drum Trap

- Floor Trap / Nahni Trap

- Grease Trap

- Gully Trap

- Intercepting Trap

- Low-Level Bath Trap

- P Trap

- Q Trap

- Running Trap

- S Trap

- Straight-Through Trap

- Bell trap: As mentioned before, A bell trap is a type of plumbing trap that is typically used to prevent sewer gases from entering a building. The trap is called a bell trap because of its shape, which is similar to a bell. The bell trap is often used in situations where a traditional P-trap cannot be installed due to space limitations. It is composed of a horizontal section of pipe connected to the drain pipe and a vertical section of pipe that is connected to the sewer line. The vertical section of pipe is designed to be lower than the horizontal section of pipe, which creates a small area of trapped water.

- Bottle trap: A bottle trap is similar to a P-trap, but it has a more compact design. It is called a bottle trap because of its shape, which is similar to a bottle. The bottle trap is typically used for sinks and other fixtures that have limited space underneath them. It works by trapping a small amount of water in the curved section of the trap, which creates a barrier that prevents sewer gases from entering the building.

- Building trap: A building trap is a device that is installed at the main drain line of a building to prevent sewer gases from entering the building. The building trap is typically installed in the basement or crawl space of a building. It works by trapping a small amount of water in the trap, which creates a barrier that prevents sewer gases from entering the building.

- Drum trap: A drum trap is a type of plumbing trap that is typically used for sinks and other fixtures that have limited space underneath them. The trap is called a drum trap because of its shape, which is similar to a drum. It is composed of a horizontal section of pipe that is connected to the drain pipe and a vertical section of pipe that is connected to the sewer line. The vertical section of pipe is designed to be lower than the horizontal section of pipe, which creates a small area of trapped water.

- Floor trap/Nahni trap: A floor trap is a device that is installed in the floor of a building to prevent sewer gases from entering the building. The floor trap is typically installed in the basement or crawl space of a building. It works by trapping a small amount of water in the trap, which creates a barrier that prevents sewer gases from entering the building. It’s also called a Nahni trap and is used in older buildings where space is limited.

- Grease trap: A grease trap is a device that is installed in the drainage system of a building to prevent grease from entering the sewer system. Grease traps work by separating the grease and other floating substances from the wastewater, allowing the clean water to pass through to the sewer system. They’re typically installed in commercial kitchens, restaurants and other food-related businesses.

- Gully trap: A gully trap is a device that is installed at the point where a drain enters a building. It works by trapping a small amount of water in the trap, which creates a barrier that prevents sewer gases from entering the building. Gully traps are typically installed in commercial and industrial buildings, as well as in areas where there is a high water table.

- Intercepting trap: An intercepting trap is a device that is installed in a building’s drainage system to prevent sewer gases from entering the building. The intercepting trap is typically installed in the main drain line of a building, and it works by trapping a small amount of water in the trap, which creates a barrier that prevents sewer gases from entering the building.

- Low-Level Bath Trap: A low-level bath trap is a type of plumbing trap that is typically used for bathtubs. It is called a low-level bath trap because it is designed to be installed at a lower level than a traditional bath trap. The low-level bath trap is typically used when there is limited space behind the bathtub or when the bathtub is installed on a slab floor. The trap works by trapping a small amount of water in the trap, which creates a barrier that prevents sewer gases from entering the building.

- P trap: As I previously mentioned, A P-trap is a plumbing device that is designed to prevent sewer gases from entering a building. It is called a P-trap because of its shape, which is similar to the letter “P.” The P-trap is installed underneath the sink, and it is typically made up of two parts: a curved section of pipe and a removable elbow joint. The water in the P-trap creates a seal that prevents the sewer gases from entering the building. It’s the most common type of trap and is effective in preventing the gases from coming inside the building.

- Q trap: It’s not a widely used type of trap. A Q-trap is similar to a P-trap, but it has a different shape. It is typically used in situations where a traditional P-trap cannot be installed. The shape of Q-trap allows it to fit into tight spaces, making it a good option for some types of installation.

- Running trap: A running trap is a type of plumbing trap that is typically used for sinks and other fixtures that have a continuous flow of water. The trap is called a running trap because it allows water to run through it continuously. A running trap typically uses a float valve to keep a certain amount of water in the trap, which creates a barrier that prevents sewer gases from entering the building.

- S Trap: As mentioned before, an S-trap is similar to a P-trap, but it does not have the curved section of pipe. Instead, the S-trap uses the water in the horizontal section of pipe to create the seal that prevents the sewer gases from entering the building. Because the S-trap relies on the water in the horizontal section of pipe, it is not as effective at preventing sewer gases from entering the building as the P-trap is. S-traps are illegal in most places because of the way it seals, it’s not recommended to use this trap.

- Straight-Through Trap: A Straight-Through trap, unlike P-trap or S-trap, does not have any curved sections in it. Instead, it consists of straight sections of pipe that are connected together. This design allows for a more efficient flow of water and typically used for fixtures that have high flow rate, such as urinals, washing machines and similar. But, as it does not hold any water, it is not used to prevent sewer gases from entering the building.