Chain surveying is a fundamental surveying technique that involves measuring linear distances using a chain or tape, primarily for mapping smaller, less complex areas. It has been used for centuries, providing foundational data that aids in property boundaries, land division, and even construction layouts. This method is known for its simplicity and is often the first form of surveying taught to students.

Chain surveying’s simplicity and practicality make it valuable for projects that do not require detailed topographical data, making it suitable for flat or slightly undulating land.

| Section | Subtopics |

|---|---|

| 1. Introduction to Chain Surveying | Overview, Importance, Historical Background |

| 2. Principles of Chain Surveying | Fundamental Concepts, Basic Terminology, Principles Behind Chain Surveying |

| 3. Types of Chains and Equipment | Metric Chains, Gunter’s Chain, Engineer’s Chain, Steel Band, Other Accessories |

| 4. Measurement Units in Chain Surveying | Units of Measurement, Conversion, Importance of Accuracy |

| 5. Methods of Chain Surveying | Whole Circle Bearing, Quadrant Bearing, Observing the Chain |

| 6. Steps Involved in Chain Surveying | Reconnaissance, Station Marking, Measuring, Recording, Errors and Corrections |

| 7. Equipment Used in Chain Surveying | Chains, Arrows, Cross Staff, Ranging Rods, Surveying Compass |

| 8. Advantages of Chain Surveying | Simplicity, Cost-Effectiveness, Accuracy for Short Distances |

| 9. Limitations of Chain Surveying | Limited Use in Complex Terrains, Accuracy Limitations, Environmental Factors |

| 10. Techniques of Taking Measurements | Direct Measurement, Chaining on Flat and Sloped Surfaces, Using Cross Staff |

| 11. Plotting Chain Survey Data | Preparing Field Book, Plotting Methods, Ensuring Accuracy |

| 12. Errors in Chain Surveying | Types of Errors (Systematic, Accidental, Cumulative), Causes, Mitigation Strategies |

| 13. Correction Methods for Errors | Correction Techniques for Length, Temperature, and Sag Errors |

| 14. Applications of Chain Surveying | Land Surveying, Archaeological Mapping, Agriculture, Infrastructure Development |

| 15. Safety Precautions in Chain Surveying | Safety in Field Work, Handling Equipment, Environmental Awareness |

| 16. Chain Surveying vs. Other Surveying Methods | Comparison with Compass, Plane Table, Theodolite, and Digital Surveying |

| 17. Tips for Beginners in Chain Surveying | Common Mistakes to Avoid, Tips for Accurate Measurements |

| 18. Chain Surveying in Modern Times | Integration with Digital Technology, Use in GIS and Remote Sensing |

| 19. Case Studies and Real-Life Applications | Examples from Land Development, Archaeology, Agricultural Land Mapping |

| 20. FAQs on Chain Surveying | Frequently Asked Questions on Equipment, Techniques, Errors, and Modern Relevance |

2. Principles of Chain Surveying

Fundamental Concepts

Chain surveying is grounded in the principles of distance measurement and linear mapping. By measuring straight-line distances between two points and plotting them, surveyors create a base map of the area in question.

Basic Terminology

- Station Points: Fixed points where measurements begin or end.

- Chain Line: The direct path where the chain is laid out.

- Offsets: Measurements taken perpendicular to the main chain line to identify features to the side.

Principles Behind Chain Surveying

The core principle is triangulation, where the survey area is divided into a series of triangles. This method is preferred because triangles are geometrically simple and can be used to measure any enclosed area accurately.

3. Types of Chains and Equipment

Metric Chains

These are standardized chains, often in lengths of 20 or 30 meters, with links marked for easy measurement.

Gunter’s Chain

One of the oldest forms, used mainly in English-speaking countries, measures 66 feet and is often used for land measurement in areas where the imperial system is prevalent.

Engineer’s Chain

Typically 100 feet long, it is preferred for construction surveying and engineering projects, where higher accuracy over longer distances is required.

Steel Band

Steel bands offer more durability and are useful in various environments, from dense vegetation to urban construction zones.

4. Measurement Units in Chain Surveying

Chain surveying uses traditional units like meters and feet. Conversions may be required depending on the type of project and its geographical location.

Conversion and Importance of Accuracy

Accuracy is critical, especially in fields where property boundaries or construction layout are involved. Conversion tables and calculators are used when switching between units to maintain measurement consistency.

5. Methods of Chain Surveying

- Whole Circle Bearing (WCB): A method where angles are measured clockwise from the north direction to locate points.

- Quadrant Bearing (QB): Uses four quadrants (NE, SE, SW, NW) to locate points relative to north and south directions.

6. Steps Involved in Chain Surveying

1. Reconnaissance

The surveyor observes the area, identifying key points and obstacles before beginning the measurement.

2. Station Marking

Markers or flags are used to denote starting and ending points, often called stations.

3. Measuring and Recording

Using chains, distances between station points are measured. The process involves several iterations to ensure accuracy.

4. Errors and Corrections

During measurement, errors can arise from environmental factors or equipment wear. These are corrected based on established techniques.

7. Equipment Used in Chain Surveying

- Chains and Tapes: Used for linear measurements.

- Arrows: Placed at each measurement’s endpoint.

- Cross Staff: Assists in marking right angles and offsets.

- Ranging Rods: Used to mark points along the chain line for alignment.

- Surveying Compass: Measures directions and bearings.

8. Advantages of Chain Surveying

Chain surveying offers a range of benefits:

- Cost-effective: Minimal equipment is required.

- Ease of Use: Simple methods that can be learned quickly.

- Reliable for Small Areas: Ensures accuracy in confined and uncomplicated terrain.

9. Limitations of Chain Surveying

- Limited Terrain Use: Not suitable for complex, mountainous, or heavily vegetated regions.

- Accuracy Challenges: Errors can accumulate over long distances.

- Environmental Influence: Temperature and weather can affect chain length and accuracy.

10. Techniques of Taking Measurements

Measurements are typically taken using two methods:

- Direct Measurement: Where the chain is laid out on flat surfaces.

- Chaining on Sloped Surfaces: Adjustments are made for slope angle to ensure accuracy in hilly or uneven terrains.

11. Plotting Chain Survey Data

Field data is recorded in a field book and plotted using conventional symbols and scales. This data helps create maps and layouts of surveyed land.

12. Errors in Chain Surveying

Errors in chain surveying are classified into:

- Systematic Errors: Occur due to equipment issues, like chain length variations.

- Accidental Errors: Arise from human error, such as misreading the chain.

- Cumulative Errors: Errors that add up over a long distance.

13. Correction Methods for Errors

Common correction methods include:

- Length Corrections: Adjustments if the chain is too long or too short.

- Temperature Corrections: Chains expand or contract with temperature.

- Sag Corrections: Applied when chains sag between two points.

14. Applications of Chain Surveying

Chain surveying is applied in:

- Land Surveying: For property boundary establishment.

- Archaeological Mapping: To document site layouts.

- Agriculture: Helps in land division and irrigation planning.

- Infrastructure Development: Used for site layout and planning.

15. Safety Precautions in Chain Surveying

Field surveyors must ensure they:

- Use equipment correctly.

- Maintain environmental awareness, especially on uneven terrain.

- Wear appropriate safety gear, including gloves and boots.

16. Chain Surveying vs. Other Surveying Methods

Chain surveying is distinct from:

- Compass Surveying: Which involves direction measurement.

- Theodolite Surveying: Provides higher precision for angles.

- Digital Surveying: Uses electronic tools and software.

17. Tips for Beginners in Chain Surveying

- Ensure Straight Chains: Avoid loops or bends during measurement.

- Practice Correct Recording: Properly record data for easy plotting.

- Work as a Team: Effective communication with helpers is key to accuracy.

18. Chain Surveying in Modern Times

Today, chain surveying is sometimes integrated with:

- Digital Tools: GPS and GIS to improve accuracy.

- Remote Sensing: For inaccessible areas.

19. Case Studies and Real-Life Applications

Land Development Example

In rural land division, chain surveying provides reliable layouts without requiring advanced technology.

20. FAQs on Chain Surveying

**Q1: What is the primary use of

chain surveying?**

Chain surveying is primarily used for mapping land and setting property boundaries on simple, flat terrains.

Q2: What causes errors in chain surveying?

Errors can arise from environmental factors like temperature changes, equipment wear, and human error.

Q3: How is chain surveying different from digital surveying?

While chain surveying uses manual methods for linear distance measurement, digital surveying employs technology, providing more precision and speed.

Q4: What are common instruments used in chain surveying?

Chains, tapes, cross-staff, arrows, and ranging rods are typical instruments.

Q5: Can chain surveying be used on complex terrains?

No, it is best suited for flat or slightly sloping areas due to limitations in managing obstacles and uneven ground.

Q6: Why is accuracy important in chain surveying?

Accurate measurements are critical for boundary establishment, ensuring legal compliance and preventing land disputes.

What is Chain Surveying | Principles of Chain Surveying | Types of Chains Used in Surveying | Principle of Chain Surveying | Procedure of Chain Surveying | Obstacles in Chain Surveying

This article includes the definition of chain survey along with all detailed information with necessary images about various aspects of chain surveying, Chain Surveying -Procedure, principle , Instrument, Objectives , Types of Chain Surveying. Surveying chain image is given Below. We Will also discuss types of chain surveying in civil engineering.

what is chain surveying in civil engineering

Chain surveying is the branch of surveying in which only linear measurements are made in the field. This is suitable for the survey of small areas with simple details and a fairly flat area. It works on the principle of Chain Triangulation. This means that the area to survey is spilled into several small triangles.

What is Chain Surveying ?? Chain survey is the simplest method of surveying. In chain survey, only measurements are taken in the field, and the rest work, such as plotting calculation etc. are done in the office.

Here only linear measurements are made i.e. no angular measurements are made. This is most suitably adapted to small plane areas with very few details. If carefully done, it gives quite accurate results.

Chain Surveying Definition

Definition of Chain Surveying – Chain Surveying is that type of surveying in which only linear measurement are made in the field. Chain surveying is suitable for surveying of small extent on open ground to secure data for exact description of the boundaries of a piece of land or to take simple details.

Instruments Used in Chain Surveying

(Survey Instruments)

The necessary requirements for field work are –

- Arrows (Arrows in Surveying)

- Chain or Tape

- Hammer

- Offset Rods

- Offset Rods

- Pegs

- Range Rod (Ranging Rod)

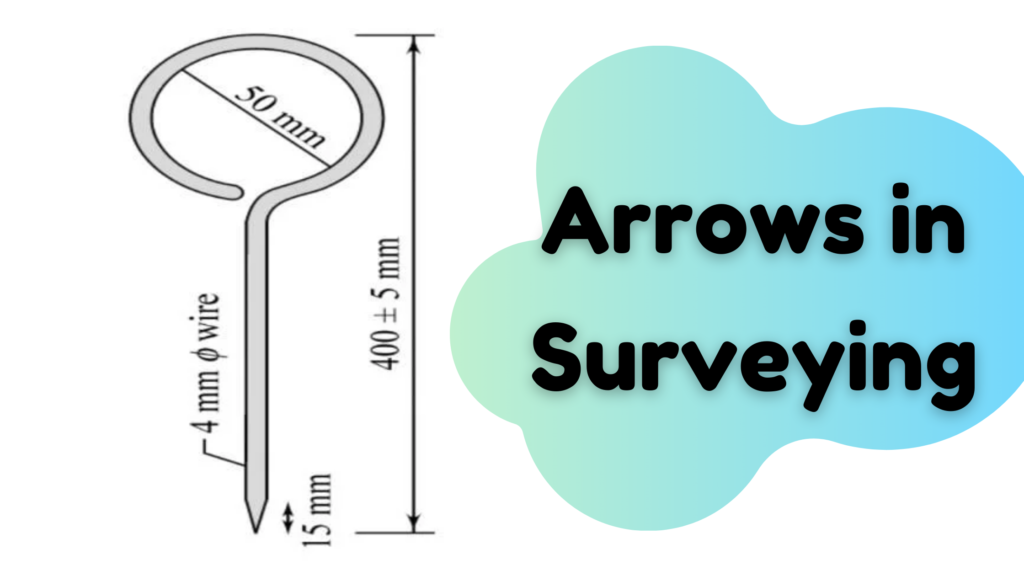

1. Arrows (Arrows in Surveying)

When measuring the length of a chain, 10 arrows are placed along the chain to properly mark the end of the chain and calculate the total chain length.

The arrow measures 4 mm in length. Soft steel wire is used to make a good diameter. The lower end is curved, while the upper end has a 5 cm loop.

It has a black enamel finish. 1842-1901 IS It measures 40 cm in length.

Chain or Tape

Chain Surveying

- Chain Triangulation

- Survey Stations

- Survey Lines

- Locating Ground Features: Offsets

- Field Book

- Field Work

- Instruments for Setting Out Right Angles

- Basic Problems in Chaining

- Obstacles in Chaining

- Cross Staff Survey

- Plotting a Chain Survey

The principle of chain surveying or chain triangulation as it is sometime called is to provide a framework consisting of a number of connected triangles.

Suitability of Chain Survey

Chain survey is suitable in the following cases:

- The area to be surveyed is comparatively small

- The ground is fairly level

- The area is open and

- Details to be filled up are simple and less.

Types Of Chain In Surveying

Chains are surveying measuring instruments made up of 100 links of 4mm galvanised mild steel wire. Three circular or oval wire rings connect these links. The flexibility of the chains is provided by these rings.

There are many different types of Surveying chains in use today.

- Metric chain

- Gunter’s chain to surveyor chain

- Engineer’s chain

- Revenue chain

Meters, centimetres, feet, inches, acre, yards, and so on are just a few examples of measurement units. There are various instruments used in the measurements of any entity, just as there are various units. Chains are one of the instruments used in measurement.

Depending upon the length of the chain, these are divide into following types,

What is Survey Station?

What is station in chain surveying?

Survey stations are of two kinds-:

- Main Stations

- Subsidiary or tie

Main Stations (Survey stations)

Main stations are the end of the lines, which command the boundaries of the survey, and the lines joining the main stations recalled the main survey line or the chain lines.

Subsidiary or the tie stations

Subsidiary or the tie stations are the points selected on the main survey lines, where it is necessary to locate the interior detail such as fences, hedges, building etc.

Tie or subsidiary lines in Chain Surveying

A tie line joints two fixed points on the main survey lines. It helps to check the accuracy of surveying and to locate the interior details. The position of each tie line should be close to some features, such as paths, building etc.

Base Lines in Chain Surveying

It is the main and longest line, which passes approximately through the center of the field. All the other measurements to show the details of the work are taken with respect to this line.

Check Line in Chain Surveying

A check-line also termed as a proof-line is a line joining the apex of a triangle to some fixed points on any two sides of a triangle. A check-line is measured to check the accuracy of the framework. The length of a checking line, as measured on the ground should agree with its length on the plan.

Offsets in Chain Surveying

What is offset in chain surveying ?? Offsets are the lateral measurements from the baseline to fix the positions of the different objects of the work with respect to the baseline. These are generally set at right angle offsets. It can also be drawn with the help of a tape.

There are two kinds of offsets:

- Perpendicular offsets

- Oblique offsets.

The measurements are taken at right angle to the survey line called perpendicular or right-angled offsets. For setting perpendicular offsets any one of the following methods is used:

- Swinging

- Using cross staffs

- Using optical or prism square

Perpendicular Offset by Swinging:

The chain is stretched along the survey line. An assistant holds the end of the tape on the object.

Surveyor swings the tape on chain line and selects the point on the chain where offset distance is the least and notes chain reading as well as offset reading in a field book on a neat sketch of the object. Perpendicular Offsets Using Cross Staffs.

Three different types of cross staffs used for setting perpendicular offsets. All cross staffs are having two perpendicular lines of sights.

The cross staffs are mounted on a stand. The first line of sight is set along the chain line and without disturbing setting right angle line of sight is checked to locate the object.

With open cross staff (Fig. 12.14 (a)) it is possible to set perpendicular only, while with french cross staff (Fig. 12.14 (b)), an even 45º angle can be set. Adjustable cross staff can be used to set any angle also since there are graduations and upperdrum can be rotated over a lower drum.

Field Book in Chain Surveying

All observations and measurements taken during chain surveying are to be recorded in a standard field book. It is an oblong book of size 200 mm × 120 mm, which can be carried in the pocket. There are two forms of the book (i) single line and (ii) double line.

The pages of a single book are having a red line along the length of the paper in the middle of the width. It indicates the chain line.

All chain-ages are written across it. The space on either side of the line is used for sketching the object and for noting offset distances.

In double line book, there are two blue lines with a space of 15 to 20 mm in the middle of each book. The space between the two lines is utilized for noting the chain-ages. Figure 12.17 shows typical pages of field books.

Survey Stations:- The fixed Points

Survey Lines:- Base Lines, Check Lines, Tie Lines

Chain surveying – Survey Stations and survey lines

Survey line and Baseline:- The line joining the main survey stations are called main survey line. The biggest of the main survey line is called the baseline and the various survey stations are plotted with reference to these. If the area to be surveyed has more than three straight boundaries, the field measurements must be so arranged that they can be plotted by laying down the triangles.

Check Lines(Proof Lines):– Check lines are the lines which are run in the field to check the accuracy of the work. The length of the check line measured in the field must agree with its length on the plan.A check line may be laid by joining the apex of the triangle to any point on the opposite side or by joining two points on any two sides of a triangle. Each triangle must have a checking line.

Tie Lines:- A Tie line is a line which joins subsidiary or tie stations on the mainline. The main object of running a tie line is to take the details of nearby objects but it also serves the purpose of check lines. The accuracy in the location of the objects depends upon the accuracy in laying the tie line.

Conditions to be fulfilled by Survey lines or Survey stations:-

- Survey stations must be mutually visible

- Survey lines must be as few as possible. So that the framework can be plotted easily.

- The framework must have one, or 2 baselines.

- The main lines should form well-conditioned triangles.

- Each triangle for the caution of the framework must be provided with sufficient check lines.

Chain Surveying Procedure

- Reconnaissance: The preliminary inspection of the area to be surveyed is called reconnaissance. The surveyor inspects the area to be surveyed, surveyor prepares index sketch or key plan.

- Marking Station: Surveyor fixes up the required no stations at places from where maximum possible stations are possible.

Some of the methods used for marking are:

- Fixing ranging poles

- Driving pegs

- Marking a cross if the ground is hard

- Digging and fixing a stone.

What is the basic principle of chain surveying?

The principle of chain surveying is triangulation. This means that the area to survey is spilled into a number of small triangles which should be well-conditioned.

In chain surveying, the side of the triangles are measured directly from the field by chain or tape, and no angular measurements are used. Here, the check lines and tie lines control the accuracy of the given work.

It is noted that plotting triangles requires no angular measurements to be made if the three sides are known.

Chain surveying used in this situation

- More or less level of the ground surface.

- A small area is to be surveyed.

- A small-scale map is to be prepared.

- The formation of well-conditioned triangles is easy.

Chain surveying is unsuitable when

- The area is crowded with many details.

- The area consists of too many undulations.

- The area is very large.

- The formation of well-conditioned triangles becomes difficult because of obstacles.

Obstacles in Chain Surveying

- Ranging obstructed

- Chaining obstructed

- Possible to chain around the obstructed

- Impossible to a chain around the obstacle

Obstructed in Chaining & Ranging

Chain Surveying Related QUESTION AND ANSWER

A trangle is said to be well-conditioned when its angles should lie between

Perpendicular offsets my be taken by setting the right angle in the ratio

Oblique offset consider

Number of offset consider

Limiting length of offset

The size of the field book is

Different type of cross staff

What the principle of chain surveying?

Chain survey is recommended when the are is

In chain survey, the area is divided into

The sketch prepared during reconnaissance survey is known as the

The working principle of the optical square is based on

The field records of the chain survey is entered in a/an

The chainman who drags the chain is called the

The Preliminary inspection of the area to be surveyed is known as

The limiting length of offset depends upon the

If a wooded area obstructs the chain line then it is crossed by the

For taking an oblique offset which makes an angle of 450 with the chain line, the instrument used is the

The main survey stations are located on the ground by

A flag is provided on a ranging rod when the ranging distance exceeds about

A cross-staff is used for

The position of a point can be fixed more accurately by

The main object of running a tie line is

Which of the following angles can be set out with the help of French cross-staff?

What is Chain Surveying?

Chain Surveying is a traditional surveying method that is used to measure horizontal distances and angles between points on the ground. It is one of the oldest and most basic forms of surveying and is still widely used today.

How is Chain Surveying different from other surveying methods?

Chain Surveying is different from other surveying methods in that it is a manual method that involves physically measuring distances and angles using a chain or tape measure. This method is often used for small-scale surveys, where the area to be surveyed is relatively small and the level of accuracy required is not extremely high. Other surveying methods, such as Total Station Surveying and GPS Surveying, use electronic equipment to make measurements and are often used for larger-scale projects or projects where a high level of accuracy is required.

What equipment is required for Chain Surveying?

The equipment required for Chain Surveying includes a chain or tape measure, a compass or theodolite for measuring angles, a leveling instrument such as a dumpy level for determining elevations, and a set of ranging rods or wooden stakes to mark the positions of survey points.

How is the survey data collected in Chain Surveying?

In Chain Surveying, the survey data is collected by measuring distances and angles between points on the ground. The surveyor will typically start at a known point and use the chain or tape measure to measure the distance to the next point. The compass or theodolite is then used to measure the angle between the line connecting the two points and a reference line, such as a north-south line. This process is repeated for each point in the survey, with the surveyor moving from point to point and measuring the distances and angles between them.

How is the accuracy of Chain Surveying measured?

The accuracy of Chain Surveying is typically measured in terms of the error or deviation from the true value of the measurements. The level of accuracy required for a particular survey will depend on the specific application and the intended use of the survey data. In general, Chain Surveying is considered to be less accurate than other surveying methods, such as Total Station Surveying or GPS Surveying.

What are the advantages and disadvantages of Chain Surveying?

The advantages of Chain Surveying include its simplicity and low cost, as well as its flexibility for small-scale surveys. The disadvantages include its lower accuracy compared to other methods and the potential for human error.

How is Chain Surveying used in land development and construction?

Chain Surveying is commonly used in land development and construction for tasks such as boundary surveys, layout of building foundations, and construction staking. It is also used in topographic surveys to determine the shape and contours of the land.

Can Chain Surveying be used for topographic surveys?

While Chain Surveying can be used for topographic surveys, it is generally considered less accurate and efficient than other surveying methods such as Total Station Surveying or GPS Surveying.

What are the common errors in Chain Surveying and how can they be corrected?

Common errors in Chain Surveying include incorrect measurement of distances or angles, incorrect recording of data, and errors in the leveling of the instrument. These errors can be corrected by re-measuring the affected points and double-checking the data for accuracy.

How has technology impacted the process of Chain Surveying?

In recent years, technology has impacted the process of Chain Surveying by providing new tools and equipment that can improve the accuracy and efficiency of the survey. For example, electronic distance measuring devices and data collectors can be used to quickly and accurately measure distances and record data, and software can be used to process and analyze the survey data.