A soak pit, also known as a soakaway or leach pit, is a covered chamber with porous walls that allows water to slowly soak into the ground. Pre-settled effluent from a Collection and Storage/Treatment or (Semi-) Centralized Treatment system is discharged into an underground chamber, where it infiltrates into the surrounding soil.

Small particles are filtered out by the soil matrix as wastewater (greywater or blackwater after primary treatment) percolates through the soil from the soak pit, and organics are digested by microorganisms. Soak pits work best with soil that has good absorptive properties; clay, hard packed, or rocky soil are not suitable.

In this article, the basic functions and reasons for using a soak pit in wastewater management are briefly discussed.

Why Soak Pit?

The water that emerges from a primary treatment chamber isn’t completely clean. A septic tank, a biogas settler, anaerobic baffled reactor, twin-pits, and other primary treatment units are examples.

The effluent water from these units is known as greywater, and it must be treated partially before being released into the ground soil. The majority of the wastewater management system requires a soak pit for this partial treatment.

Wastewater from the primary treatment unit will not be reused. However, discharging effluent water into the environment after partial treatment through a soak pit is a safer option.

Soak Pit’s Function

The greywater that passes through the soak pit is filtered. As a result, smaller effluent particles settle at the bottom of the soak pit. These smaller particles are digested by microorganisms, resulting in a long-term degradation process. The filtered water is then released through the soak pit’s porous wall.

The following are the main functions of a soak pit in general:

- The soak pit is used to collect effluent water from the primary treatment unit.

- The effluent water from the primary treatment unit is sent to the soak pit for partial treatment.

- The soak pit emits clean, non-hazardous water to the ground.

- The soak pit is constructed in such a way that the treated water emerges from the porous walls.

- The soak pit aids in the replenishment of groundwater bodies.

Design of Soak Pit

Design Considerations

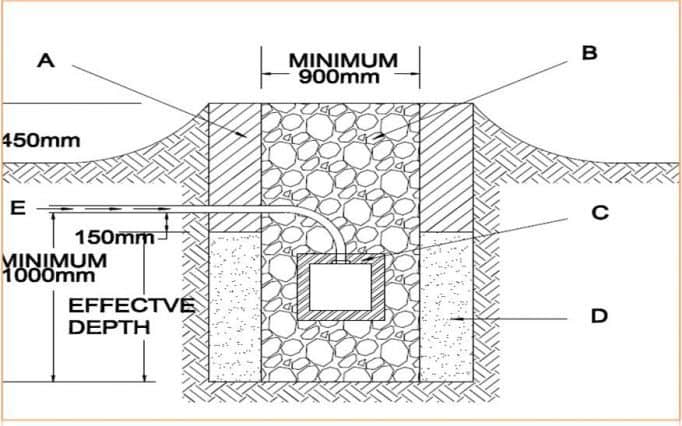

The soak pit should be between 1.5 and 4 metres deep, but never less than 2 metres above the groundwater table as a thumb rule. It should be kept at a safe distance from a source of drinking water (ideally more than 30 m).

The soak pit should be placed away from high-traffic areas to avoid compacting the soil above and around it. It can be left unlined and filled with coarse rocks and gravel, or it can be left empty and lined with a porous material to provide support and prevent collapse.

The rocks and gravel will keep the walls from collapsing while still allowing enough space for the wastewater to flow through.

To help disperse the flow, a layer of sand and fine gravel should be spread across the bottom in both cases. A removable (preferably concrete) lid should be used to seal the pit until it needs to be maintained in the future to allow for future access.

Soak Pit Construction Step by Step

Soak Pit Construction Step by Step – How to Construct Soak Pit?

Step 1

Excavation of earth inverted level from natural ground level. We do excavation upto 3800 mm from natural ground level.

Step 2

Do first P.C.C. 150 mm thick and 900 mm wide around in dig where brick wall stay. Use M15 grade for P.C.C. Bottom brick wall thickness keep 600 mm wide and height keep also 600 mm. Offset of P.C.C left same both side 150mm.

Step 3

Do brick work over 600mm wide brick wall. We do 450 mm wide brick masonry wall on it and height keep 600 mm.

Step 4

Do 345 mm wide brick wall above natural ground level. Minimum height of brick masonry wall keep 300 mm high from natural ground level.

Step 5

After that we cover it from precast slab. Thickness of R.C.C. keep 130 mm or 150 mm thick. Minimum grade of concrete slab keep M20. Slab level keep 450 mm high from natural ground level.

Step 6

For cleaning purpose we leave 600*800 mm wide manhole in concrete slab of soak pit.

Soak Pit Appropriateness

A soak pit will quickly clog if it does not provide adequate treatment for raw wastewater. It should be used to discharge blackwater or greywater that has been settled.

Soak pits are suitable for rural and peri-urban areas. They require soil with a high absorption capacity. They are not suitable for areas that are prone to flooding or have high groundwater levels.

Operation & Maintenance of Soak Pit

Without maintenance, a well-sized soak pit should last between 3 and 5 years. To extend the life of a soak pit, make sure the effluent has been clarified and/or filtered to prevent solids from building up excessively.

The pit will eventually become clogged with particles and biomass, and it will need to be cleaned or relocated. The material inside the soak pit can be excavated and refilled if the performance of the soak pit deteriorates.

Pros & Cons of Soak Pit

| Pros Of Soak Pit | Cons Of Soak Pit |

| Can be built and repaired using materials that are readily available in the area. | To avoid clogging, a primary treatment is required. |

| For all users, this technique is simple to implement. | Could have a negative impact on soil and groundwater properties |

| A small amount of land is required. | – – – |

| Low initial and ongoing capital and operating costs | – – – |