What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material’s notch toughness.

The objective of the charpy impact test ??

To determine the material resistance to impact from a swinging pendulum.

To test the resistance of the material towards an impact load

Apparatus used in the charpy impact test ??

Charpy Testing machine, a rod of mild steel and a rod of carbonate steel.

- Charpy Impact Test

- Charpy Impact Test Specimen

- Charpy Impact Test Specimen Dimensions

- Charpy Impact Test Specimen Size

- Charpy Impact Test Specimen Preparation

- Charpy Impact Test Procedure

- Charpy Impact Test Procedure

- Charpy Impact Testing Machine

- Charpy Impact Testing Machine Diagram

- Charpy Impact Testing Machine Price

- Charpy Impact Test PDF

- Charpy Impact Test Standard

- Charpy Impact Test ASTM Standard

- Charpy Impact Test ISO Standard

- Charpy Impact Test Results

- Charpy Impact Test Lab Report

- Charpy Impact Test Diagram

Introduction:

the charpy impact test is one of the impact-testing that is used to determine the resistance towards a sudden load or impact. Impacted specimens with small fracture or with a very little plastic deformation is said to be in a brittle manner whereas fracture of metal after extensive plastic deformation is said to be in a ductile manner. Brittle fracture looks clear, shiny with surfaces while ductile fracture looks greyish and fibrous.

What is the Procedure of the charpy impact test??

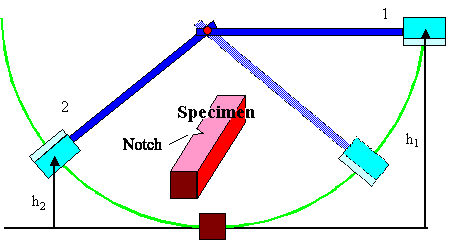

- A Charpy V-notch specimen is placed across parallel jaws in the impact-testing machine.

- The pointer is being set up to it’s maximum value (300 J).

- The hammer is released from the initial height downward towards the sample.

- Observations and the energy absorbed is recorded and tabulated.

- Step 1-3 is repeated for another type of metal.

The result of the charpy impact test ??

Mild Steel Carbon Steel

Discussion about the charpy impact test ??

From the results obtained from the experiment, we can see that the specimen fracture differently. The mild steel fracture but did not break completely and some part of the steel still attached therefore it is said to be in a ductile manner. The carbon steel is said to be in a brittle manner although it is harder. The carbon specimen broke completely into 2 parts and the broken surfaces look smoother than the mild steel.

Carbon steel has lower ductility compared to the mild steel but the carbon steel is more brittle than the mild steel. This is because carbon steel has high percentage of carbon in it (percentage of carbon in mild steel is less than 0.2%) that lower the ability to absorb energy when sudden load is given.

From the way both specimen cracks and the ‘grayish and fibrous’ broken surfaces of the mild steel shows that it undergoes plastic deformation and in a ductile manner. The carbon steel experience less plastic deformation and the surfaces look smoother and shiny.

Ductile fracture is better because of the following reasons:

a) More energy needed in the ductile fracture because it is a tough material

b) Brittle fracture happens quickly without warning while the ductile fracture took a long time before the whole process to happen

Charpy Impact Test Conclusion

From the charpy impact test, carbon steel undergoes brittle fracture while the mild steel undergoes ductile fracture. More energy is absorbed by mild steel shows that it is more suitable to be used in the structural construction that exposure to high load for example car body.

*****

The standard Charpy-V notch specimen is 55mm long, 10mm square and has a 2mm deep notch with a tip radius of 0.25mm machined on one face.

In some circumstances, sub-size Charpy specimens can be tested with thickness less than 10mm. The specimen is supported at its two ends on an anvil and struck on the opposite face to the notch by the pendulum.

The amount of energy absorbed in fracturing the test-piece is measured and this gives an indication of the notch toughness of the test material.

The pendulum swings through during the test, the height of the swing being a measure of the amount of energy absorbed in fracturing the specimen.

Conventionally, three specimens are tested at any one temperature and the results averaged. Alternatively, tests are carried out at a range of temperatures in order to generate a ductile to brittle transition curve.

Charpy tests show whether a metal can be classified as being either brittle or ductile. This is particularly useful for ferritic steels that show a ductile to brittle transition with decreasing temperature. A brittle metal will absorb a small amount of energy when impact tested, a tough ductile metal absorbs a large amount of energy.

The appearance of a fracture surface also gives information about the type of fracture that has occurred; a brittle fracture is bright and crystalline, a ductile fracture is dull and fibrous.

The percentage crystallinity is determined by making a judgement of the amount of crystalline or brittle fracture on the surface of the broken specimen, and is a measure of the amount of brittle fracture.

Lateral expansion is a measure of the ductility of the specimen. When a ductile metal is broken, the test-piece deforms before breaking, and material is squeezed out on the sides of the compression face.

The amount by which the specimen deforms in this way is measured and expressed as millimetres of lateral expansion.

When reporting the results of a Charpy test, the absorbed energy (in J) is always reported, while the percentage crystallinity and lateral expansion are optional on the test report.

It should be emphasised that Charpy tests are qualitative, the results can only be compared with each other or with a requirement in a specification – they cannot be used to calculate the fracture toughness of a weld or parent metal.

TWI is UKAS accredited for carrying out Charpy testing to ASTM E23 and ISO 148, at a wide range of test temperatures.