WATER CEMENT RATIO | Water-Cement Ratio (W/C) of Concrete | Water cement ratio can be defined as the ratio of the volume of water to the volume of cement used in a concrete mix. Water has a great role in the strength and workability of concrete.

After lots of experiments it has been found that for a specific proportion of materials in a concrete mix, there is a certain amount of water that gives maximum strength.

Water Cement Ratio

The water–cement ratio is the ratio of the weight of water to the weight of cement used in a concrete mix.

The most important factor determining the strength of concrete is the water to cement ratio. It is the ratio of weight of mixing water (free water available for the reaction with cement) to that of cement in the mixture.

Cement needs water of about 38% by weight for complete hydration. But since the complete hydration is a long term process, and under practical conditions, the period of concrete mixing and casting being short, the cement combines with only 23% of water.

If only 23% of water is added while mixing, the concrete won’t be workable because the water-cement ratio of 0.23 will be too less.

So additional water will be required for workability. This water in excess of 23% by weight will evaporate on drying of concrete, creating voids in it due to trapping of air bubbles insides, thereby reducing the strength of concrete.

Assuming full compaction, and at a given age and normal temperature, strength of concrete can be taken to be inversely proportional to the water-cement ratio. This is so called the Abrams’ law.

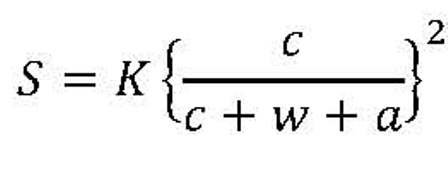

Water Cement Ratio Formula

Water Cement Ratio Formula is used to calculate Strength of concrete.

Abrams’ law is a special case of a general rule formulated empirically by Feret:

S = strength of concrete

K = a constant

c, w & a = volume of cement, water & air respectively

Degree of Hydration

Generally, strength of concrete is expressed as a function of water-cement ratio. But actually, strength at any water-cement ratio depends upon the “degree of hydration” of cement.

Strength of the concrete is dependent on solid products of hydration of cement to the space available for formation of this product: “gel/space ratio”.

The conventional relation between strength and water-cement ratio will hold good primarily for 28 days strength for fully compacted concrete.

Instead of relating the strength to water-cement ratio, the strength can be more correctly related to the solid products of hydration of cement to the space available for the formation of this product.

This ratio is defined as the ratio of the volume of the hydrated cement paste to the sum of volumes of the hydrated cement and of the capillary pores.

Aggregate to Cement ratio

The aggregate-cement ratio represents the volume of cement paste in a concrete for a given water-cement ratio. Higher the aggregate-cement ratio, lesser will be the volume of cement paste and vice-versa. Higher aggregate-cement ratio means, larger volume of concrete is occupied by the aggregates hence less proportion of cement paste.

The total volume of porosity in concrete formed after the hydration would be lower for the lower volume of cement paste used. If the total volume of porosity is lower then the strength of concrete will be higher.

It has been found that for a constant given water-cement ratio, a leaner mix leads to a higher strength.

A slight change in the amount of water causes much more differences in the strength of concrete. If less water is used, the resultant concrete will be nearly dry, hard to place in the form and may create difficulties in compaction.

Besides this, with less water, the proper setting will not be guaranteed and thus the strength of concrete get reduced considerably.

DO YOU KNOW – What is FIRE PROOF CONCRETE ??

On the other hand, if the water is used more, it may develop larger voids and honey-combing in the set concrete, in this way decreasing its density, durability, and strength. Hence, the water cement ratio attends an important role in producing concrete of required strength. The lower the ratio, the greater is the strength of concrete.

REQUIRED WATER-CEMENT RATIO

| Proportion | Water-Cement Ratio |

| 1 : 2 : 4 | 0.58 |

| 1 : 1.5 : 3 | 0.51 |

| 1 : 1: 2 | 0.43 |

In this Article, we will learn about What is Water Cement Ratio? and How to calculate WATER CEMENT RATIO??

We well knew the quantity of water is very important while concrete mixing or mortar because the durability and strength of concrete depend on the water consumption in concrete.

Workability of Concrete?

The ability of concrete to handle, transport and placing the concrete without any segregation is called as Workability of concrete.

What is water cement ratio?

The ratio between the weight of water to the weight of cement in the concrete mix is called Water Cement (W/C) ratio.

Purpose of Water

The purpose of water in concrete to composite the Cement, Sand and Coarse aggregate. In concrete, the cement was the bonding agent if the amount water increase or decrease it will affect the bonding of material and it will be a chances to lose the workability and Strength.

Water cement ratio table

Here we listed the water-cement ratio table as per IS code 10262. You can use this table for the water-cement ratio of different grade of concrete.

For easy placement of concrete, it is a general practice to mix more water, which can badly affect the quality as well as the strength of the concrete. Too much water will result in segregation of the sand and aggregate (stone chips) from the cement paste. Also concrete will experience more shrinkage as the excess water leaves, resulting in internal cracks and visible fractures (particularly around inside corners) which again will reduce the final strength.

However, a lower water-cement ratio leads to higher strength and durability but may make the mix more difficult to place.

Read About – Online Bricks Calculator 2019 & Best and Most Accurate

Therefore it always advised sticking to the correct water-cement ratio so as to get a workable concrete mix for easy placement and proper compaction without compromising the strength of the concrete.

As per general practice for 1:1½:3 concrete mix 25-30 litres water should be added per 50 kg of cement (one bag) depending upon the temperature, humidity and water associated with sand and aggregate (if any).

How to calculate the quantity of water for Concrete?

Normally, the water-cement ratio being between 0.4 to 0.6 as per IS standard.

We take 0.42 as a ratio of W/C.

Quantity of water = 0.42 x 50 = 21 Liters (1 bag cement = 50 Kg)

So the required quantity of water is 21 Liters per cement bag.

We shall interpret the Water cement ratio by Thumb Rule Calculation for M15 grade concrete.

M15 Ratio 1:2:4

cement = 317 Kg (unit weight = 1440 kg/cum)

Sand = 638 Kg (unit weight = 1450 Kg/cum)

Blue Metal = 1478 Kg (unit weight = 1680 Kg/Cum)

Total = 316.8+638+1478 = 2433 Kg

unit weight of Water = 1000 Kg

Water ratio = 1000/2433 = 0.41

What is the Right Water-Cement Ratio for Mix Design?

Water Cement Ratio (W/C) of Concrete

The water in concrete has to perform the following two functions:

(i) The water enters into chemical action with cement and this action causes the setting and hardening of concrete.

(ii) The water lubricates the aggregates and it facilitates the passage of cement through voids of aggregates. This means that water makes the concrete workable.

It is found theoretically that water required for these two functions is about 0.50 to 0.60 times the weight of cement. This ratio of the amount of water to the amount of cement by weight is termed as the water-cement ratio and the strength and quality of concrete primarily depend upon this ratio.

The quantity of water is usually expressed in litres per bag of cement and hence the water-cement ratio reduces to the quantity of water required in litres per kg of cement as 1 litre of water weighs 1 kg. For instance, if water required for,

1 bag of cement is 30 litres, the water-cement ratio is equal to 30/50= 0.60

The important points to be observed in connection with the water-cement ratio are as follows:

(i) The minimum quantity of water should be used to have a reasonable degree of workability. The excess water occupies space in concrete and on evaporation. the voids are created in concrete. Thus the excess water affects considerably the strength and durability of concrete. In general, it may be stated that addition of one extra litre of water to the concrete of one bag of cement will reduce its strength by about 1.47 N/mm2 In other words, the strength of concrete is inversely proportional to the water-cement ratio.

(ii) The water-cement ratio for structures which are exposed to weather should be carefully decided. For instance, for structures which are regularly wetting and drying, the water-cement ratio by weight should be 0.45 and 0.55 for thin sections and mass concrete respectively. For structures which are continuously under water, the water-cement ratio by weight should be 0.55 and 0.65 for thin sections and mass concrete respectively.

(iii) Some rules-of-thumb are developed for deciding the quantity of water ii concrete. The two such rules are mentioned below. The rules are ordinary concrete and they assume that the materials are non-absorbent and dry.

(a) Weight of water = of the weight of the cement + 4% of the weight of total aggregate.

(b) Weight of water = of the weight of the cement + 5% of the weight of total aggregate.