Concrete Slump Cone Test Procedure | Applications | Types | Uses – Slump test procedure is performed to check the workability of concrete. A good workable concrete has good strength.

What is Workability of Concrete?

Workability is a complex property of concrete which is defined as the ease with which it can be mixed, transported and placed in position within a homogeneous state. Workability depends upon the quantity of water, aggregate grade and percentage of fine materials in the mix.

Many researchers have tried with different parameters to measure the workability of the concrete and later found some of the tests which are very close to check the workability.

The following tests are commonly employed to check the workability of concrete.

- #Test 1. Slump test

- #Test 2. Compaction factor test

- #Test 3. Flow test

- #Test 4. Kelly ball test

- #Test 5. Vee-Bee consistometer test.

- #Test 6. K-Slump Test

Concrete Slump Cone Test or Slump Cone Test of Concrete

Concrete slump test or slump cone test is to determine the workability or consistency of concrete mix prepared at the laboratory or the construction site during the progress of the work. Concrete slump test is carried out from batch to batch to check the uniform quality of concrete during construction.

The slump test is the most simple workability test for concrete, involves low cost and provides immediate results. Due to this fact, it has been widely used for workability tests since 1922. The slump is carried out as per procedures mentioned in ASTM C143 in the United States, IS: 1199 – 1959 in India and EN 12350-2 in Europe.

Concrete Slump Test International Standard

1- American Society for Testing and Materials (ASTM): ASTM slump test standards are ASTM C 143, ASTM C143M.

2- The American Association of State Highway and Transportation Officials (AASHTO): AASHTO slump test standards are AASHTO T119, AASHTO BS1881.

3- British & European standard: British & European slump test standard is BS EN 12350-2.

4- Indian standard: The Slump test IS Code in india is IS: 1199 – 1959.

Generally concrete slump value is used to find the workability, which indicates water-cement ratio, but there are various factors including properties of materials, mixing methods, dosage, admixtures etc. also affect the concrete slump value.

Although it is very easy to perform this method. But it is not suitable for very wet or very dry concrete.

This test can be used as a control test and gives an indication of the concrete uniformity from batch to batch. Repeated batches of the same mix, brought to the same slump, will have the same water content and water cement ratio, weights of aggregate, cement and admixtures are uniform and aggregate grading is within acceptable limits.

Apparatus Required for Concrete Slump Cone Test

The apparatus required for conducting Slump test are Mettalic Mould which is in the shape of frustum cone, A tamping rod with bullet end, Scale or tape for measuring the slump. Metallic sheet for placing Slump and trowel for pouring concrete in the slump.

The mold for the test is in the form of the frustum of a cone having height 30 cm, bottom diameter 20 cm and top diameter 10 cm. The tamping rod is of steel 16 mm diameter and 60cm long and rounded at one end.

- Metallic Mould

- Tamping Rod

- Scale / Tape

- Metallic Sheet

- Trowel

Concrete Slump Cone Test Procedure

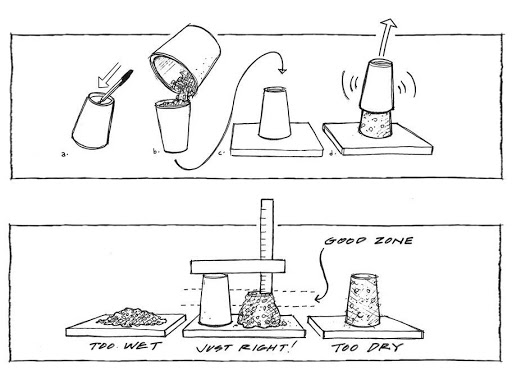

- STEP #1. Thoroughly clean the inner surface of Frustum cone and it should be free from moisture content and adherence of any old set concrete.

- STEP #2. Now place the Mould (Cone) on the metallic steel plate or on any smooth surface.

- STEP #3. Fill the cone with concrete in four layers each with an approximate height of 1/4th of the mould.

- STEP #4. Each layer is tamped 25 times by tamping rod taking care to distribute the strokes evenly over the cross section.

- STEP #5. Now after filling the 4th layer, the concrete is struck off with the trowel.

- STEP #6. The mould is removed from the concrete immediately in a vertical direction by raising it slowly and carefully.

- STEP #7. This allows the concrete to subside. This subsidence is called a SLUMP.

Concrete Slump Cone Test Value Observation:

The slump (Vertical settlement) measured shall be recorded in terms of millimeters of subsidence of the specimen during the test.

Results of Concrete Slump Cone Test on Concrete

Here is the slump cone test result.

Slump for the given sample= _____mm

When the slump test is carried out, following are the shape of the concrete slump that can be observed:

Factors which influence the concrete slump test:

- Material properties like chemistry, fineness, particle size distribution, moisture

content and temperature of cementitious materials. Size, texture, combined grading, cleanliness and moisture content of the aggregates, - Chemical admixtures dosage, type, combination, interaction, sequence of addition and its effectiveness,

- Air content of concrete,

- Concrete batching, mixing and transporting methods and equipment,

- Temperature of the concrete,

- Sampling of concrete, slump-testing technique and the condition of test equipment,

- The amount of free water in the concrete, and

- Time since mixing of concrete at the time of testing.