A deep foundation is a type of foundation that transfers building loads to the earth farther down from the surface than a shallow foundation does to a subsurface layer or a range of depths.

A pile or piling is a vertical structural element of a deep foundation, driven or drilled deep into the ground at the building site. There are many reasons that a geotechnical engineer would recommend a deep foundation over a shallow foundation, such as for a skyscraper.

Some of the common reasons are very large design loads, a poor soil at shallow depth, or site constraints like property lines. There are different terms used to describe different types of deep foundations including the pile (which is analogous to a pole), the pier (which is analogous to a column), drilled shafts, and caissons.

Piles are generally driven into the ground in situ; other deep foundations are typically put in place using excavation and drilling. The naming conventions may vary between engineering disciplines and firms. Deep foundations can be made out of timber, steel, reinforced concrete or prestressed concrete.

Here is a systematic breakdown of the requested topic related to deep foundations and piles:

Types of Piles

1. Based on Function

- End-Bearing Piles: Transfer load to a strong stratum at the tip of the pile (e.g., rock or dense soil). The load is carried entirely by the base of the pile.

- Friction Piles: Transfer load to surrounding soil through skin friction between the pile surface and soil. Used when a strong stratum is not accessible.

- Combination Piles: Use both end-bearing and friction to support the load.

2. Based on Material

Timber Piles:

- Made from tree trunks, usually treated to prevent decay.

- Used for light loads and temporary structures.

- Prone to rot if exposed to air and water alternately.

Concrete Piles:

- Can be precast or cast in situ.

- Durable and resistant to corrosion in aggressive soils.

- Precast piles require heavy handling and driving equipment.

Steel Piles:

- Made of H-sections, pipes, or other steel forms.

- Can penetrate hard layers easily due to their small cross-sectional area.

- Prone to corrosion in marine environments unless protected.

Composite Piles:

- Combine the strengths of materials like steel and concrete.

- Example: Steel core with a concrete coating or timber piles encased in concrete.

3. Based on Construction Method

- Driven Piles: Pre-manufactured piles driven into the ground using hammers or vibratory drivers.

- Bored Piles: Constructed by drilling holes and filling them with concrete, often reinforced.

- Screw Piles: Installed by screwing helical blades into the ground, suitable for softer soils.

Friction and End-Bearing Piles

- Friction Piles rely on the adhesion between the pile and soil. These are effective in loose sands and cohesive soils.

- End-Bearing Piles rely on hard strata to support the load. The tip of the pile rests on a firm layer such as rock.

Pile Load Capacity: Static Formulae

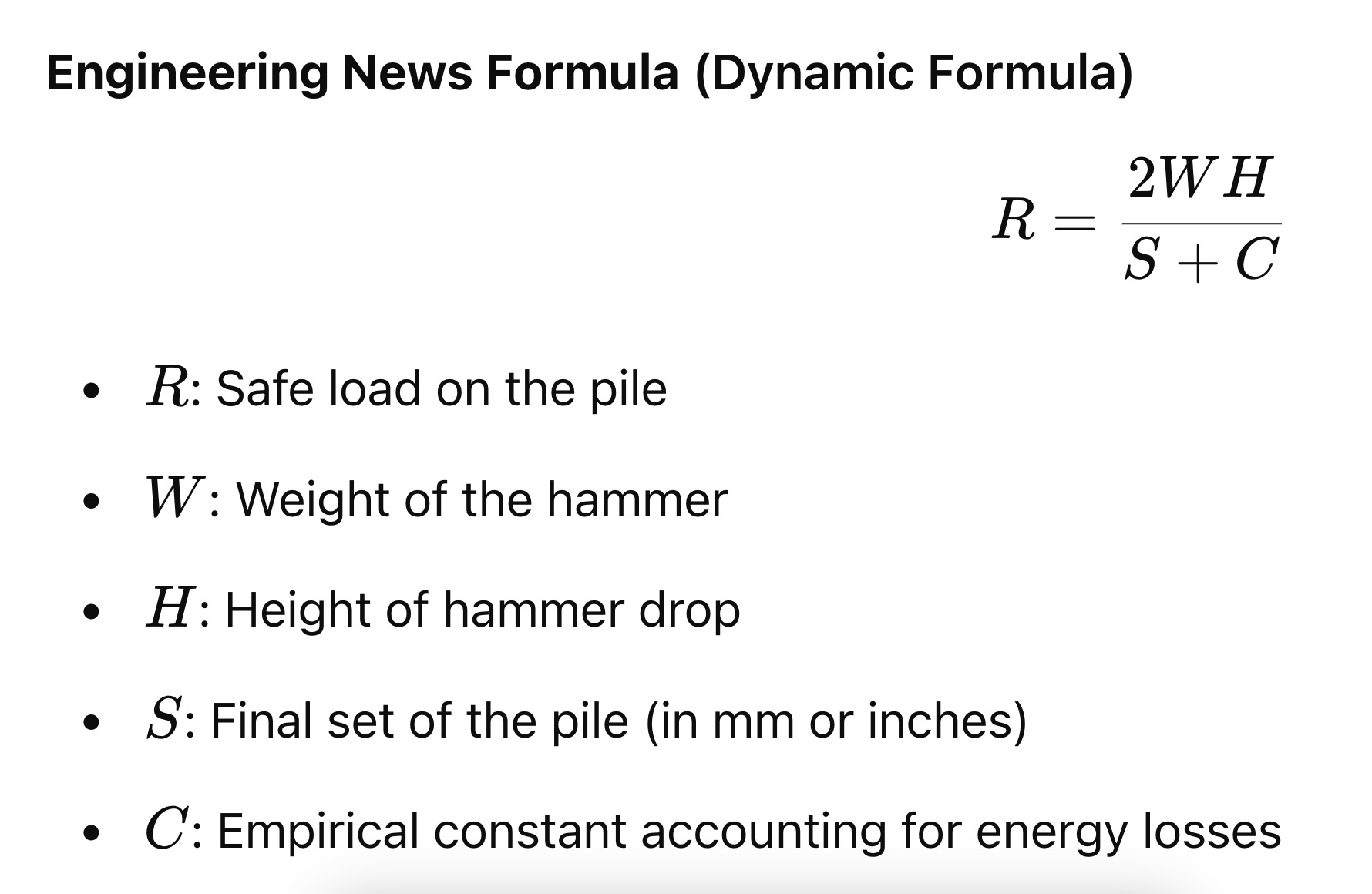

1. Engineering News Formula (Dynamic Formula)

- R: Safe load on the pile

- W: Weight of the hammer

- H: Height of hammer drop

- S: Final set of the pile (in mm or inches)

- C: Empirical constant accounting for energy losses

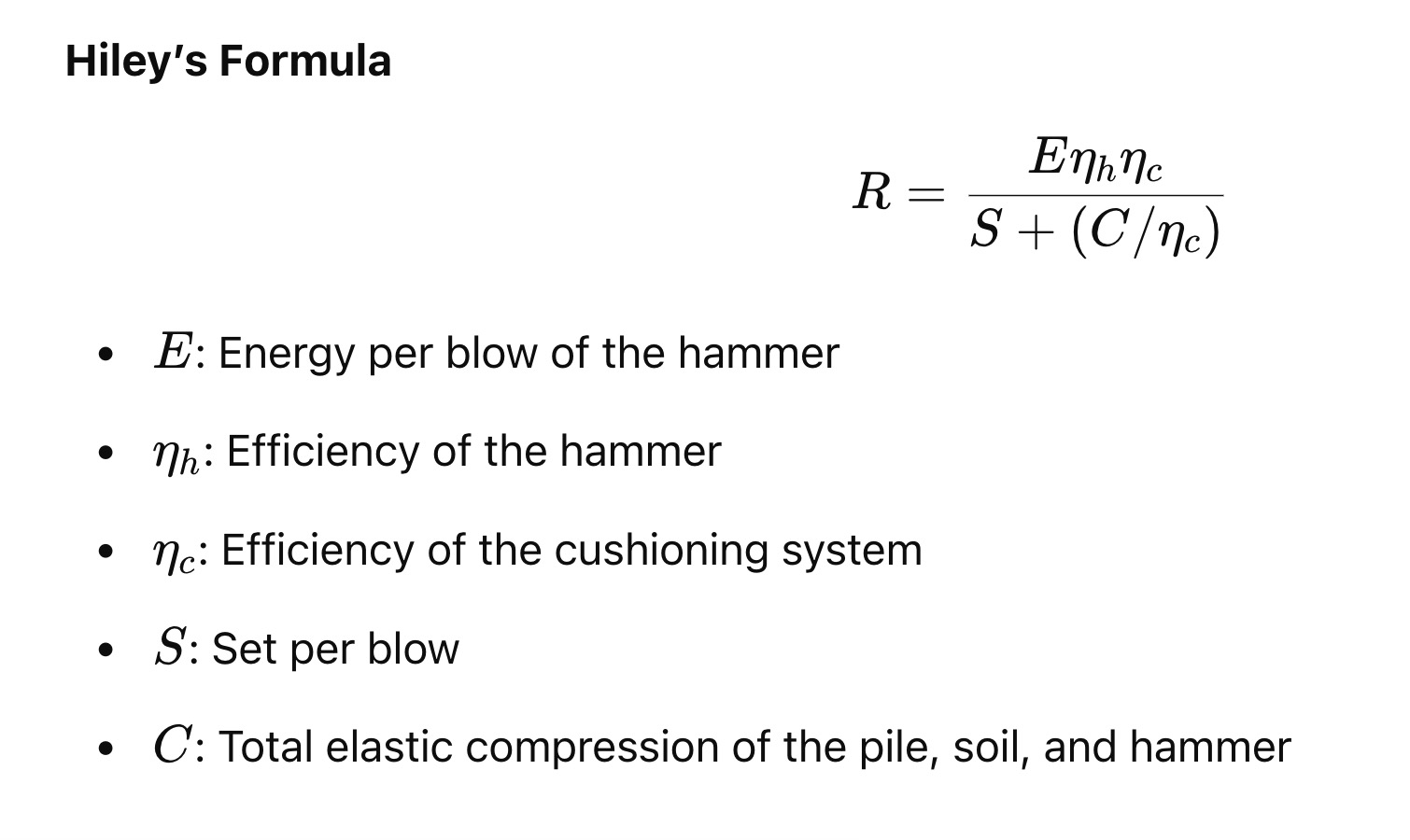

2. Hiley’s Formula

- E: Energy per blow of the hammer

- ηh: Efficiency of the hammer

- ηc: Efficiency of the cushioning system

- S: Set per blow

- C: Total elastic compression of the pile, soil, and hammer

Group Action in Piles

When piles are used in groups, the load capacity is influenced by the interaction between the piles.

- Block Failure: A group of piles behaves as a single block of soil and piles. The failure occurs when the block of soil around the piles moves together.

- Settlement of Pile Groups: Settlement depends on soil type:

- Sands: Settlements are often smaller and occur quickly.

- Clays: Settlements are larger and occur slowly due to consolidation.

Pile Load Test

A pile load test is conducted to determine the safe load capacity of a pile.

- Types:

- Static Load Test: A gradually increasing load is applied to the pile to measure deflection.

- Dynamic Load Test: Monitors the pile’s response to hammer blows.

Negative Skin Friction

Negative skin friction occurs when the surrounding soil settles more than the pile, creating a downward drag force on the pile surface. This typically occurs in consolidating clay or loose fill.

Effects:

- Increases the pile load.

- Reduces the pile’s load-carrying capacity.

Solutions:

- Using sleeves or coatings to reduce friction.

- Extending the pile to reach deeper strata.

Under-Reamed Piles

Under-reamed piles are bored piles with one or more enlarged bulb-like bases (referred to as “under-reams”).

- Applications: Commonly used in expansive soils like black cotton soil.

- Advantages: Provides additional bearing capacity and prevents uplift due to soil expansion.