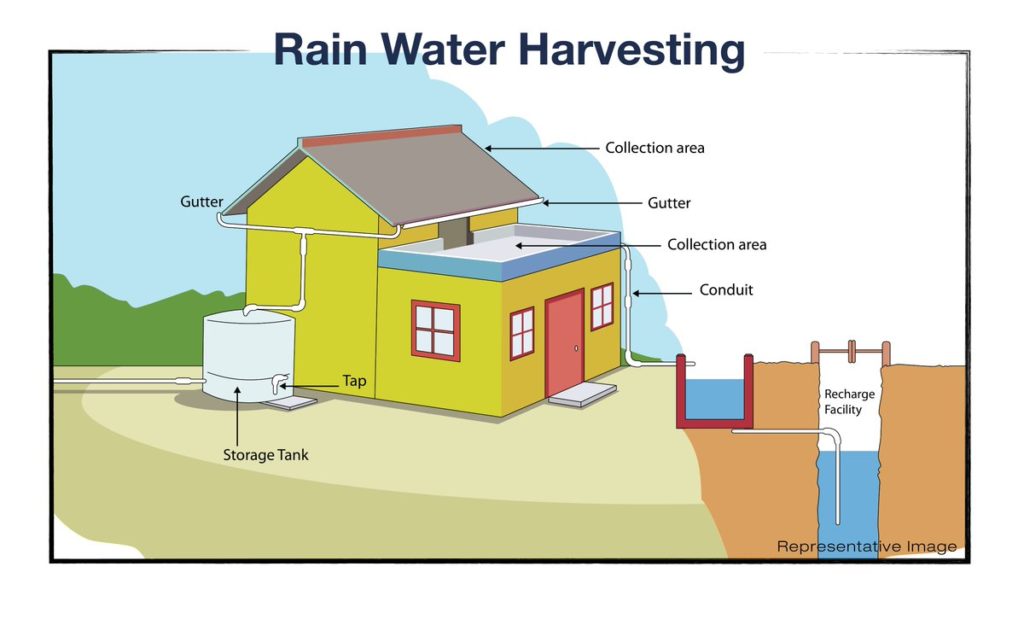

Rainwater harvesting components are used for transporting rainwater through pipes or drains, filtration and tanks for storage of harvested water. Rooftop Rainwater Harvesting is for Recharging Shallow Groundwater.

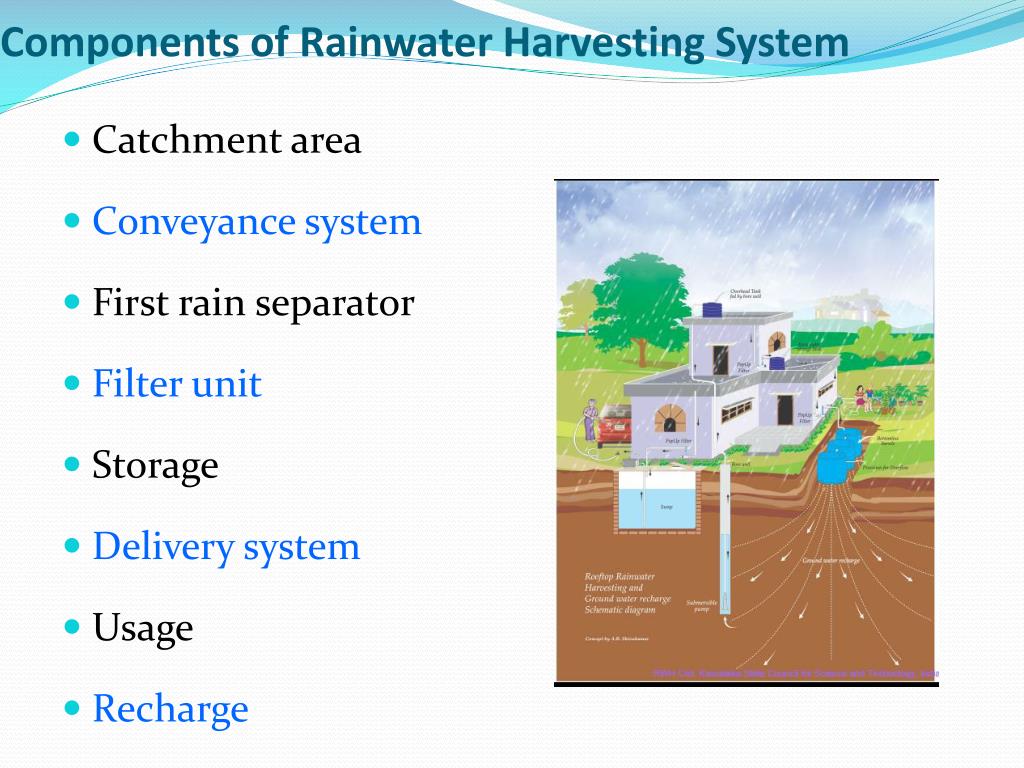

Components of Rainwater Harvesting System

Any rainwater harvesting system has three components: Catchment, Conveyance, and Storage. There are two classes of rainwater harvesting systems: Systems which collect roof runoff for household use. The common components of a rainwater harvesting system (Rainwater Harvesting Components) are:

- Catchments

- Coarse mesh

- Gutters

- Conduits

- First flush

- Filters

- Storage tanks, and

- Recharge structures

1. Catchments

The surface that receives the rainfall directly and transfers water to the system is called catchment area. It can be a paved area such as a building’s terrace or patio, or an unpaved area such as a lawn or open field. Often usable for water harvesting is a roof made of reinforced cement concrete ( RCC), galvanized iron or corrugated sheets.

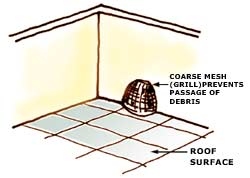

2. Coarse Mesh

Coarse Mesh In Rainwater Harvesting – It prevents the passage of debris, provided in the roof.

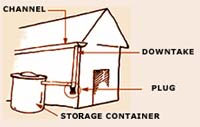

3. Gutters

Channels that circle the edge of a sloping roof to capture rainwater to the storage tank and move it. Gutters may be semi-circular or rectangular and made mainly from simple galvanised sheet of iron. Gutters need to be protected so that when filled with water, they don’t sag or fall off. The way gutters are installed depends mainly on building the house, usually iron or timber brackets are fastened into the walls.

The size of the gutter during the highest intensity rain should be according to the river. It is advisable to over dimension them by 10 to 15 per cent.

Gutters need to be protected so that when filled with water, they don’t sag or fall off. The manner in which gutters are mounted depends on the structure of the house; iron or timber brackets may be fastened into the walls, but some form of attachment to the rafters is required for houses with wider eaves.

4. Conduits

The conduits are pipelines or drains that bring rainwater to the irrigation system from the catchment or rooftop area. Conducts may be of any type, such as polyvinyl chloride ( PVC) or galvanised iron (GI), commercially available materials.

5. First-flushing

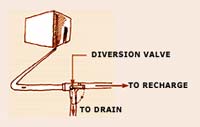

A first flush device is a valve which ensures that the runoff from the first rain spell is flushed out and is not entering the system.

This needs to be achieved, as the first rain spell brings a comparatively greater volume of air and catchment surface contaminants.

6. Filters

Using the filter, suspended contaminants are separated from rainwater accumulated over the roof. A filter unit is a chamber filled with filter media such as fibre, coarse sand and gravel layers to remove sediment and soil from water until it reaches the storage tank or recharges structure. For additional filtration Charcoal may be added.

6.1 – Charcoal water filter

A simple charcoal filter can be made in a drum or an earthen pot. The filter consists of gravel, sand and charcoal which are all generally available.

6.2 – Sand filters

Sand filters have commonly available sand as filter media. Sand filters are easy to set up and are inexpensive. These filters can be used to treat water to efficiently reduce turbidity (suspended particles such as silt and clay), colour, and microorganisms.

The top layer contains coarse sand followed by a 5-10 mm layer of gravel followed by another 5-25 cm layer of gravel and boulders in a basic sand filter that can be built domestically.

6.2.1 – Dewas filters

Most of Dewas people, Madhya Pradesh, have wells in their own homes. Previously, all that those wells would do was groundwater extraction. But then, a soilwater recharge scheme was launched by the Dewas district administration. The rooftop water was collected and allowed to pass through a filter system built by Mohan Rao, Dewas district collector, and rural engineering services engineers named the Dewas fillter. Thus filtered water is placed into the tubewell operation.

The filter consists of a 140 mm diameter and 1.2 m long pipe made of polyvinyl chloride ( PVC). Three chambers still exist. The first chamber of purification has pebbles ranging from 2-6 mm, the second chamber has much larger pebbles, from 6 mm and 12 mm, and the third chamber has the highest-12-20 mm. At the outflow side there is a mesh through which clean water flows out after going through the three chambers. This filter unit costs Rs 600.

7. Storage facility

There are different options available for the construction of these tanks in terms of form, height, construction material and tank location and they are: – Shape: Cylindrical, Square and Rectangular.

Material of construction: Reinforced cement concrete, (RCC), ferrocement, masonry, plastic (polyethylene) or metal (galvanised iron) sheets are commonly used.

Position of tank: Depending on space availability these tanks could be constructed above ground, partly underground or fully underground. Some maintenance measures like cleaning and disinfection are required to ensure the quality of water stored in the container.

8. Recharge structures

Rainwater can be charged into groundwater aquifers through any appropriate structures such as dugwells, borewells, trenches for recharge and pits for recharge.

Different recharge structures are possible-some supporting water percolation at shallower depth by soil strata (e.g. recharge trenches, permeable pavements) while others lead water to higher depths from which it enters groundwater (e.g. recharging wells). Established structures such as wells, pits, and tanks can be adjusted as recharge structures at several sites, thereby removing the need to upgrade some structures. Here are a few widely used methods for recharging:

8.1 – Recharging of dugwells and abandoned tubewells.

There are thousands of wells in alluvial and hard rock areas which either have gone dry or whose water levels have fallen considerably. This can be recharged directly by run-off from the rooftop. Rainwater collected on the building’s rooftop is redirected by drainpipes into a settlement or filtration tank, from which it flows deep into the recharge (borewell or dugwell).

If a tubewell is used for recharging, then the casing (outer pipe) should ideally be a slotted or perforated pipe so that the water can percolate more surface area. Developing a borewell will improve its recharge ability (development is the phase where water or air is forced into the well under pressure to loosen the underlying soil strata to make it more permeable).

If a dugwell is used for recharge, it should have openings (weep-holes) in the well lining at regular intervals to allow water to pass through the sides. Dugwells should be sealed to avoid the breeding of mosquitoes, and leaves and debris from entering.

The bottom of recharge wells should be desilted annually to maintain the intake capacity.

Providing the following elements in the system can ensure the quality of water entering the recharge wells:

- Filter mesh at entrance point of rooftop drains

- Settlement chamber

- Filter bed

8.2 – Settlement Tank

Settlement tanks are used to extract silt and other impurities that collect from rainwater. A settlement tank is like an ordinary storage container that has supplies for inflow (to bring water from the catchment), outflow (to take water to the recharge well) and flood.

A settlement tank may have an unpaved bottom surface that enables the percolation of standing water into the soil.

The recharge rate, particularly of borewells, may not match the rainfall rate in the event of excess rainfall. In such cases the desilting chamber retains the excess water until the recharge system soaks it up. Therefore the chamber of settlement serves as a buffer in the system.

Any reservoir, (masonry or concrete underground tanks, old unused tanks, pre-made PVC tanks or ferrocement tanks) with sufficient storage space can be used as a settling tank.