Soundness Test of Cement (Le-Chatelier Method) – It is very important that the cement after setting shall not undergo any appreciable change of volume. The soundness of cement, fly ash for concrete and lime is determined by using the Le Chatelier moulds and Le Chatelier Water Bath according to the relevant standard.

In this Detailed Guide, we will discuss What Is The Soundness Test Of Cement and Why Soundness Test Of Cement Is Done? You can also Check the Soundness Test Of Cement Procedure And Aim for your Practical Exams in Engineering Examinations.

Soundness Test of Cement (Le-Chatelier & Autoclave Method)

Certain cement has been found to undergo a large expansion after setting causing disruption of the set and hardened mass. This will cause serious difficulties for the durability of structures when such cement is used. The unsoundness in cement is due to the presence of an excess of free LIME than that could be combined with acidic oxide at the kiln. You can also explain the Soundness Test Of Cement Is Carried Out To Determine Lime Quantity in cement.

Soundness Test Of Cement Name Of Test

It is also likely that too high a proportion of magnesium content or calcium sulfate content may cause unsoundness in cement. The soundness of cement may be determined by two methods, namely the Le-Chatelier method, and the autoclave method.

-

Soundness test of cement by LE-CHATELIER METHOD

-

Soundness test of cement by AUTOCLAVE METHOD

In the soundness test, a specimen of hardened cement paste is boiled for a fixed time so that any tendency to expand is speeded up and can be detected. Soundness means the ability to resist volume expansion.

SOUNDNESS TEST OF CEMENT BY LE-CHATELIER METHOD

Soundness Test Of Cement Pdf

Soundness Test Of Cement Apparatus

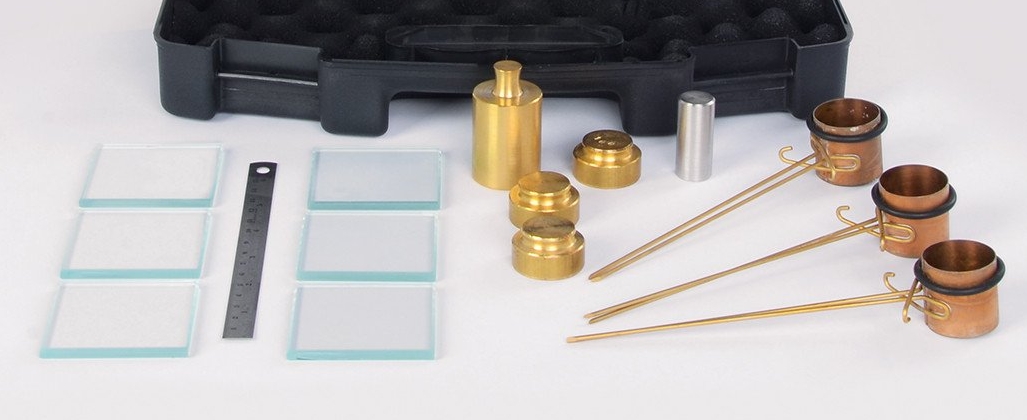

The Le Chatelier Soundness Kit is supplied complete with;

- Le Chatelier moulds 3 pcs.

- 50×50 mm glass plates 6 pcs.

- 300 gr Weights 1 pcs.

- 100 gr Weight, 3 pcs.

- Tamping Rod 17 mm dia. x 70 gr

- Steel Ruler

- Plastic Carrying Case

We Required Following apparatus for Le-Chatlier’s Soundness Test on Cement.

Apparatus List

- Le- chatelier mould

- Cement

- Glass sheets

- Mixing pan

- Trowel

- Wight

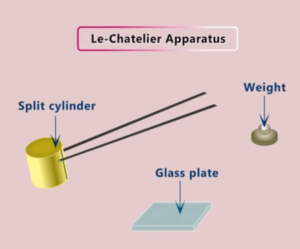

Fig. 1: Le-Chateliers Apparatus

Le- Chatelier apparatus conforming to IS : 5514-1969

Fig. 2: Schematic of Le-Chateliers Apparatus

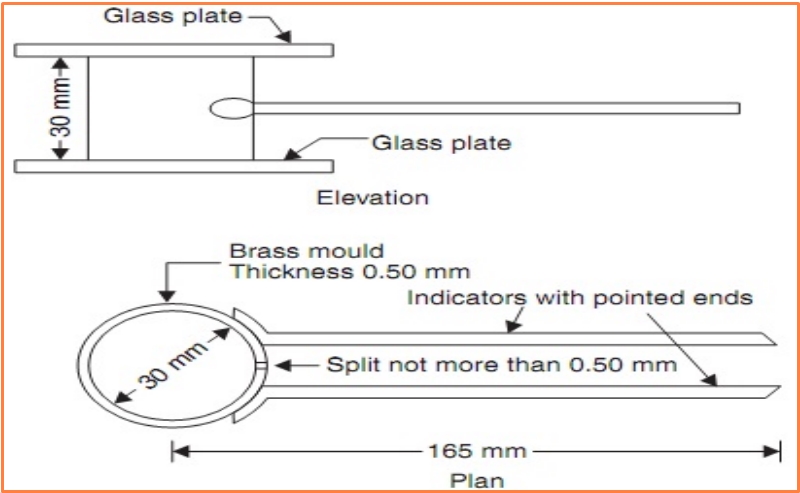

Consist of a small split cylinder of spring brass to other noncorrodible metal of 0.5mm thickness forming a mold of 30mm internal diameter and 30mm high.

On either side of the split, two indicators are brazed suitably with pointed ends made of 2mm diameter brass wire in such a way that the distance of these ends to the center of the cylinder is 165mm.

The split cylinder will be kept between two glass plates. The temperature of the molding room, dry materials and water shall be maintained at 27±2°C The relative humidity of the laboratory shall be 65 ± 5 percent.

The moist closet or moist room shall be maintained at 27 ± 2°C and at a relative humidity of not less than 90 percent.

Soundness Test Of Cement Procedure

Here is the Procedure of Soundness test of Cement by Le-Chateliers Method.

- Place the lightly oiled mold on a lightly oiled glass sheet and fill it with cement paste formed by gauging cement with 0.78 times the water required to give a paste of standard consistency. [refer IS : 4031 (Part 4 )-1988].

- Cover the mold with another piece of the lightly oiled glass sheet, place a small weight on this covering glass sheet and immediately submerge the whole assembly in the water at a temperature of 27 ± 2°C and keep there for 24 hours.

- Measure the distance separating the indicator points to the nearest 0.5 mm. Submerge the mould again in the water at the temperature prescribed above.

- Bring the water to boiling, with the mould kept submerged, in 25 to 30 minutes, and keep it boiling for three hours. Remove the mould from the water, allow it to cool and measure the distance between the indicator points.

- The difference between these two measurements indicates the expansion of the cement. This must not exceed 10 mm for ordinary, rapid hardening and low heat Portland cement. If in case the expansion is more than 10 mm as tested above, the cement is said to be unsound.

IS Code For Soundness Test Of Cement

Soundness Test Of Cement IS Code – Indian Standard (Part 3) ( First Revision) was adopted by the Bureau of Indian Standards on 24 February 1988, after the draft finalized by the Cement and Concrete Sectional Committee had been approved by the Civil Engineering Division Council. According to BIS, the Soundness Test Of Cement IS Code is “IS: 4032-1985”. You can download here.

IS 4031-3 (1988): Methods of physical tests for hydraulic cement, Part 3: Determination of soundness [CED 2: Civil Engineering]

Standard methods of testing cement are essential adjuncts to the cement specifications. This standard is different parts lays down the procedure for the tests to evaluate the physical properties of different types of hydraulic cement.

The procedure for conducting chemical tests of hydraulic cement is covered in IS: 4032-1985*.

Originally all the tests to evaluate the physical properties of hYdraulic were covered in one standard but for facilitating the use of this standard and future revisions it has been decided to print the different tests as different parts of the standard and, accordingly this revised standard has been brought out in thirteen parts.

This will also facilitate the updating of individual tests. Further, since the publication of the original standard in 1968, a number of standards covering, the requirements of different equipment used for testing of cement, a brief description of. which was also covered in the standard, had been published.

In this revision, therefore, reference is given to different instrument specifications deleting the description of the instruments, as it has been recognized that reproducible and repeatable test results can be obtained only with standard testing equipment capable of giving the desired level of accuracy. This part covers the determination of soundness by the Le-Chatelier method and the autoclave test.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS: 2-1960*.

The number of significant places retained in the rounded off value should be the same as that of the specified value in this standard.

Soundness Test Of Cement Calculation

The soundness of Cement = L1 – L2.

Where L1= Distance 1 and L2= Distance 2

L1=Measurement is taken after 24 hours of immersion in water at a temp. of 27 ± 20°C

L2=Measurement was taken after 3 hours of immersion in water at boiling temperature.

This value must not exceed 10 mm for Ordinary or OPC, Rapid, Low Heat, PPC and High alumina cement.

Soundness Test Of Cement Video

Soundness Test Of Cement Determine

|

Name of Cement

|

Standards | Expansion(max) |

|

OPC-33

|

IS269-19899

|

10mm

|

|

OPC-43

|

IS8112-1989

|

10mm

|

|

OPC-53

|

IS12269-1987

|

10mm

|

|

Rapid Hardening Cement

|

IS8041-1990

|

10mm

|

|

Low heat cement

|

IS12600-1989

|

10mm

|

|

Super sulphated

|

IS6909-1990

|

5mm

|

|

PPC Cement

|

IS1489-1991 part -1

|

10mm

|

|

PSC

|

IS455-1976

|

10mm

|

|

High alumina

|

IS6452-1989

|

5mm

|

|

SRC

|

IS12330-1988

|

10mm

|

|

Masonry

|

IS3466-1988

|

10mm

|

|

IRS-T-40

|

Railway Standards

|

5mm

|

SOUNDNESS TEST OF CEMENT BY AUTOCLAVE METHOD

Apparatus required for Soundness Test Of Cement by Autoclave Method

- Weights

- Balance

- Graduated Glass Cylinders – Graduated glass cylinders of 150 ml capacity shall be used, The permissible variation on these cylinders shall be plus or minus one milliliter. The main graduation lines of the cylinders shall be in circles and shall be numbered. The least graduations shall extend at least one-seventh of the way around, and intermediate graduations shall extend at least one-fifth of the way around the cylinder. The graduation lines may be omitted for the lowest 5 mI.

- Moulds– Moulds of 25 X 25 mm size and 282 mm internal length and other accessories conforming to IS : 10086-1982*.

- Autoclave – The autoclave shall consist of a high pressure steam boiler equipped with suitable safety device.The capacity of heating unit shall· be such that with maximum load (water plus specimens) the pressure of the saturated steam in the autoclave may be raised to a gauge pressure of 2’1 MPa or to an absolute pressure of about 2’2 MPa, in I to Ii hour from the time the heat is turned on.The automatic pressure control shall be capable of maintaining the pressure at 2’1 ± 0’1 MPa corresponding to a temperature of 215’7 ± 1’7°C, The autoclave shall be designed to permit the pressure to drop from 2’1 MPa to less than 0’07 MPa in one hour after the heat supply has been shut off, It shall be equipped with a vent valve for allowing the escape of air during the early part ofthe heating period and for releasing any steam pressure remaining at the end of the one-hour cooling period, The pressure gauge shall have a nominal dial diameter of 115 mm and shall be graduated from 0 to 4’1 MPa with scale division of not more than 0’04 MPa.The error in the gauge shall not exceed plus or minus 0’02 MPa at the operating pressure of 2’1 MPa.

- Length Comparator – Changes in length of test specimen shall be measured by an apparatus conforming to IS: 9459-1980·,

Preparation of Test Specimens for Soundness Test Of Cement by Autoclave Method

Preparation of Mould – The moulds shall be thinly covered with mineral oil. After this operation, the stainless steel or non-corroding metal reference inserts with knurl heads shall be set to obtain an effective gauge length of 250 mm, care being taken to keep them clean and free from oil.

Mixing Cement Paste– The standard batch of cement paste shall consist of 500 g of cement, mixed with sufficient water to give a paste of standard consistency, .

Moulding Specimens – Immediately following the completion of mixing, the test specimens shall be moulded in one or two layers, each layer being compacted with the thumb or forefinger by pressing the paste into the corners, around the reference inserts, and along the surfaces of the moulds until a homogeneous specimen is obtained. After the top layer has been compacted, the paste shall be cut off flush with the top of the mould and the surface smoothed with a few strokes of the trowel.: During the operations of mixing and moulding, the hand shall be protected by rubber gloves,

Storage of Test Specimen – After the mould has been filled, it shall be immediately placed in a moist closet or a moist room. Specimens shall remain in the moulds in the moist room for at least 24 h. If removed from the moulds before 24 h, they shall be kept in the moist closet or moist room until tested.

Procedure for Soundness Test Of Cement by Autoclave Method

- STEP 1. At 24 ± t h after moulding, the specimens shall be removed from the moist atmos- phere, measured for length, and placed in the autoclave at room temperature in a rackso that the four sides of each specimen shall be exposed to saturated steam.The autoclave shall contain enough water to maintain an atmosphere of saturated steam vapour during the entire period oftest. Ordinarily; 7 to 10 percent ofthe volume of the autoclave shall be occupied by water.

- To permit air to escape from the autoclave during the early portion of the heating period, the vent valve shall be left open until steam begins to escape (see 6.4), The valve shall then be closed and the temperature of the auto- . clave shall be raised at such a rate as will bring the gauge pressure of the steam to 2’1 MPa in I to Ii h from the time the heat is turned on.The 2’1 ± O’lMPa pressure shall be maintained for 3 h. At the end of 3 hours period, the heat supply shall be shut off and the autoclave cooled at a rate such that the pressure will be less than 0’1 MPa at the end of the hour, and any pressure remaining shall be slow-released by partially opening the vent valve until atmospheric pressure is attained.The autoclave shall then be opened and the test specimens immediately placed in water, the temperature of which is above 90°C.The water surrounding the bars shall·then be cooled at a uniform rate by adding cold water so that the temperature of the water shall be lowered to 27 ± 2°C in 15 min.The water surrounding the specimens shall then be maintained at 27 ± 2°C in 15 min when the specimens shall be surface-dried and their lengths measured again.

The calculation for Soundness Test Of Cement by Autoclave Method

Calculations – The difference in lengths of the test specimen before and after autoclaving shall be calculated to the nearest 0’01 percent of the effective gauge length which is the length between the innermost points of the metal inserts used as reference points and shall be reported as the autoclave expansion of the cement. A contraction ( negative expansion) shall be indicated by prefixing a minus sign to the percentage expansion reported.